Millipath

Samuelle Bourgault, and Jennifer Jacobs. 2024. Millipath: Bridging Materialist Theory and System Development for Surface Texture Fabrication. DIS 2024, Copenhagen, Denmark. doi: https://doi.org/10.1145/3643834.3661599

Proponents of digital fabrication argue that future technologies will fundamentally reshape manufacturing; however, we still have a limited understanding of the relationship between contemporary digital fabrication technologies and the values and labor of people who make things. Contemporary materialist theories can offer insights into how interaction modalities with machines and materials influence human production activities. We aim to implement these theoretical principles in technical system development. We focus on action as a bridging concept between abstract notions regarding human-machine-material relationships and concrete digital fabrication system features. We use CNC-milled surface texture production on wood as a case study. We follow a research-through-design process to develop Millipath, an action-oriented programming platform enabling the parametric design of machine toolpaths. Through the analysis of autobiographical data from fabricating artifacts, we investigate how digital fabrication systems informed by materialist theories support expressive modes of production and design decisions in response to material behaviors.

This work is part of my Ph.D. in Media Arts and Technology at the Univeristy of Califronia, Santa Barbara in the Expressive Computation Lab. In collaboration with Jennifer Jacobs.

Downloadable paper on the ECL website.

Presented at

DIS 2024, Copenhagen, Denmark

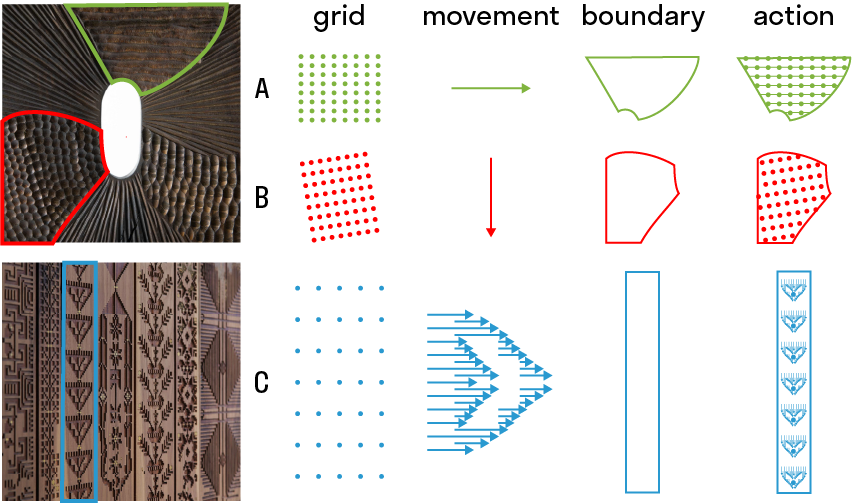

Through the analysis of a design space of carved textures, I conceptualized three design articulations – movement, grid, and boundary - as the main components of the carving action. I used sections of Fossil by Andrew Daniels (A and B) and the Shawl wall panel by the Naqsh Collective (C) to showcase how these components apply to textured surfaces.

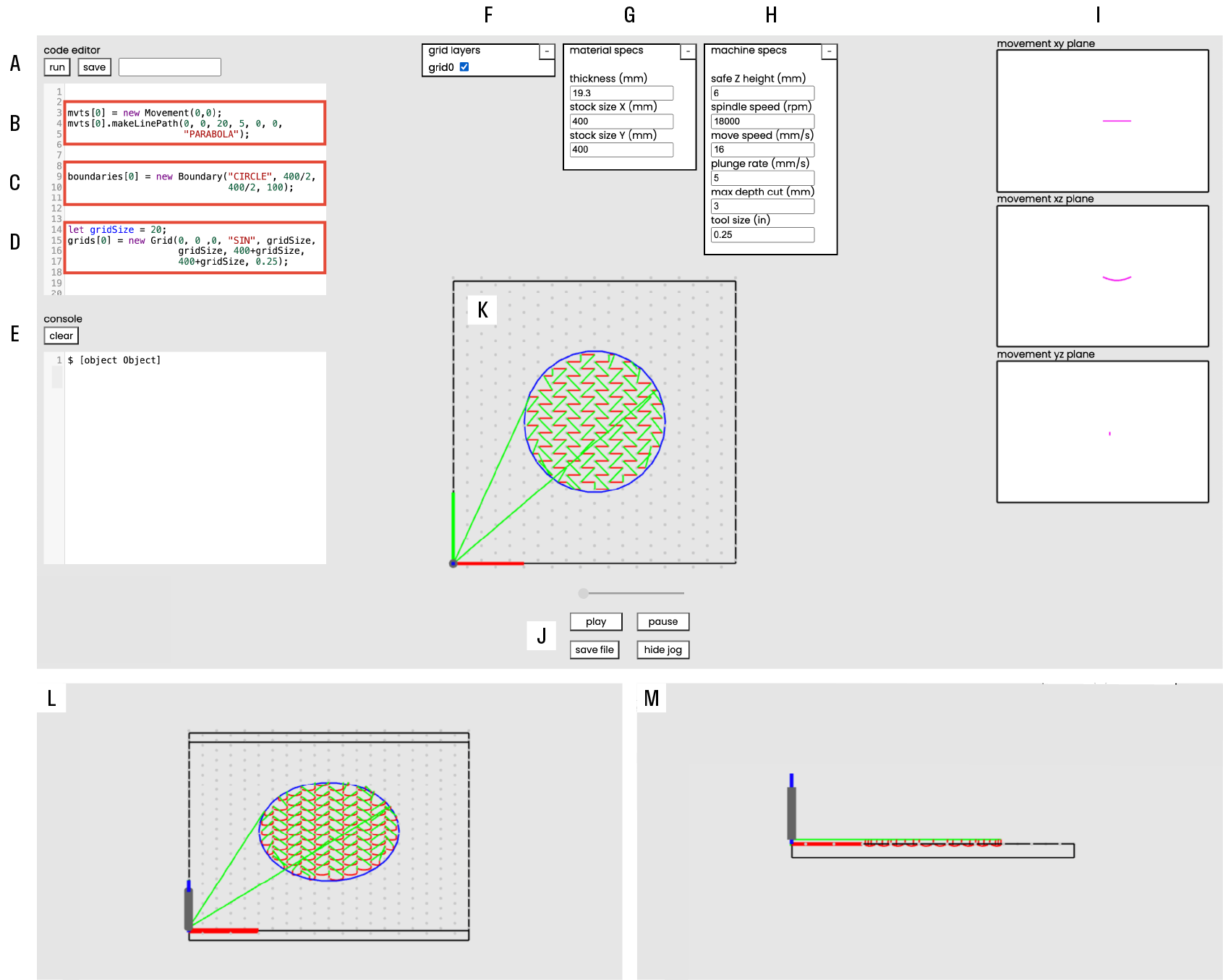

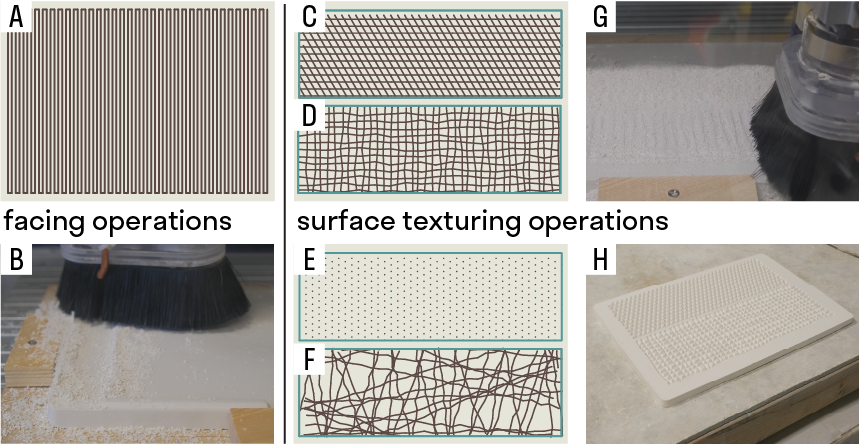

These design components informed the development of a programming platform for creating CNC-milled surface texture called Millipath. Millipath is a parametric system that enables the design and fabrication of carving actions by specifying machine toolpaths. Millipath is a web application built with the JavaScript framework p5.js where a craftsperson can specify machine movements, boundaries, and grids programmatically, and produce OpenSBP code to execute on a ShopBot CNC router.

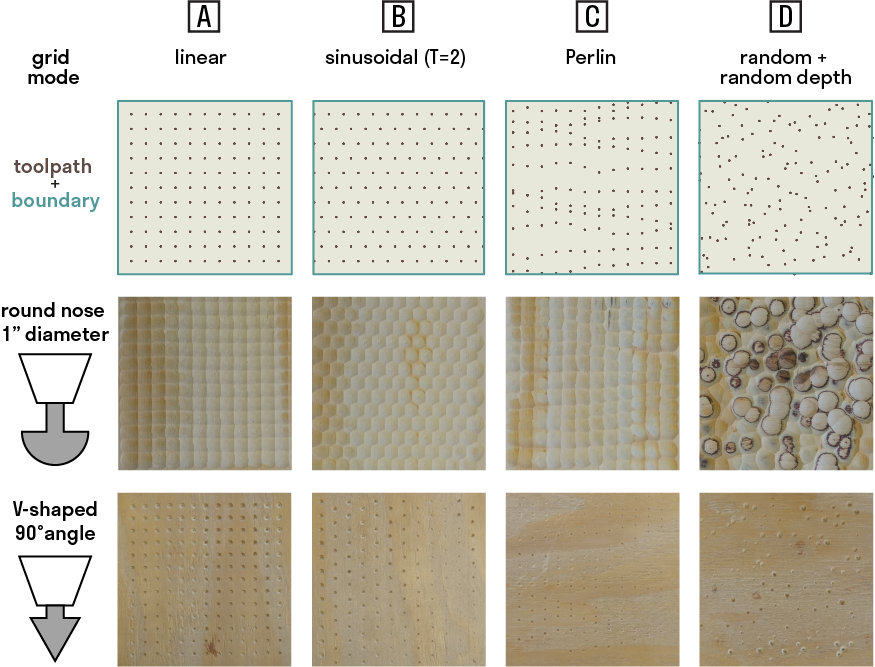

To gain insights into the expressive potential of our movementgrid-boundary model of the carving action, I applied Millipath to the design and fabrication of five collections of texture samples. The samples were designed around fve visual components that recurred systematically throughout our design space: dot, line, motif, pattern superposition, and triangle.

The dot, the motif and the superposition studies are shown below.

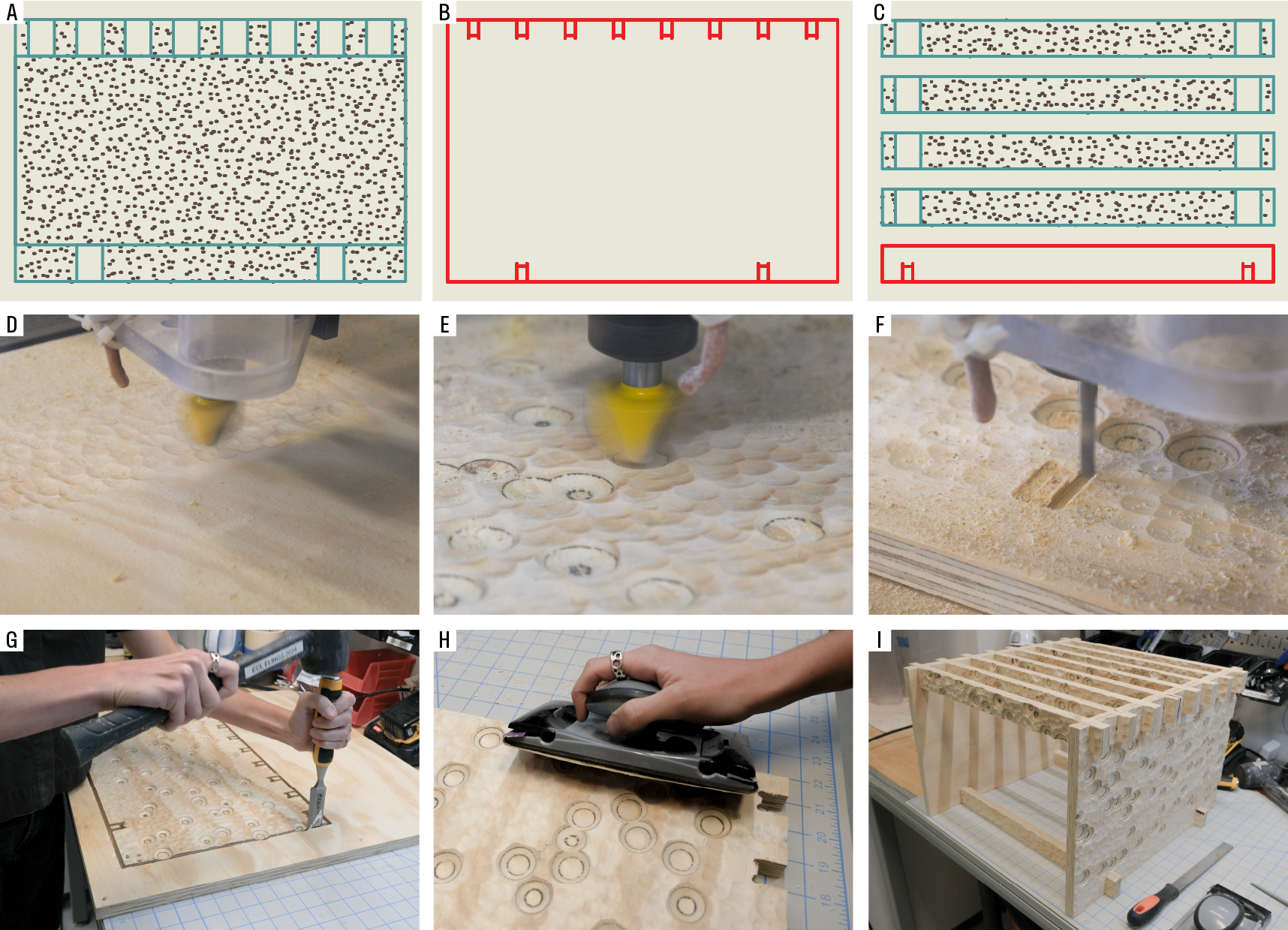

To evaluate the viability and opportunities of CNC-milled surface textures in craft production, I then used Millipath to create three artifacts using diferent materials and decorative techniques. During five months, I iterated on the design and fabrication of a plywood stool, four textured ceramic cups, and an inlaid wooden tray using the actions and visual language developed in our first studies.

For the plywood stool, I used the superposition of shallower and deeper dot patterns. This stool exemplar shows how Millipath not only facilitates the creation of surface textures but, through its grid-movement-boundary model, also enables the production of functional joinery and furniture.

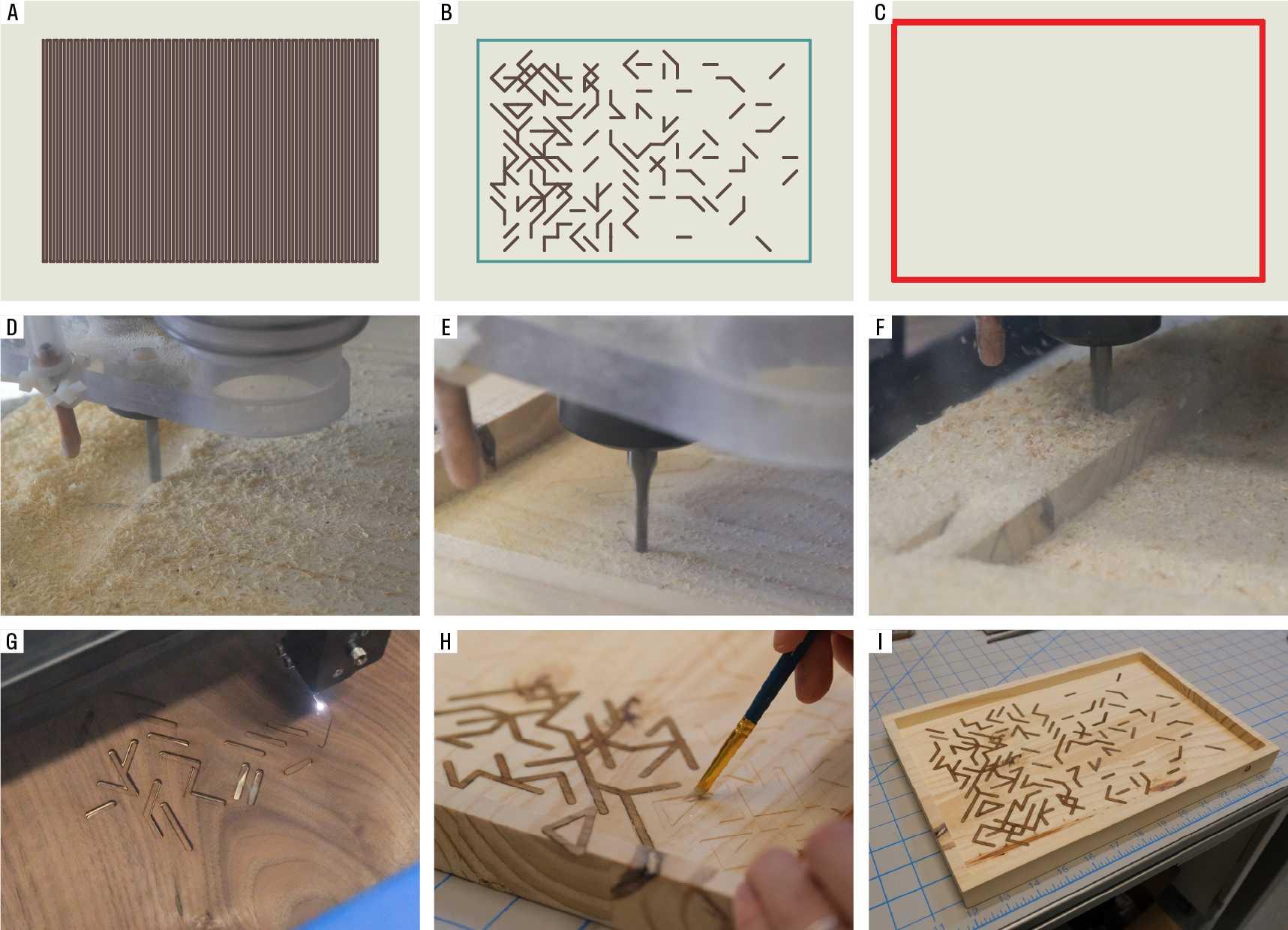

For the inlay tray, I used linear superficial action within integer rotation of pi/4. The inlay tray shows how Millipath enables the layering of operations wherein each operation is contingent on the previous one. This includes pocketing, texturing, and cutting. In addition to providing the code representation of the toolpath, Millipath generates a vectorial toolpath representation.

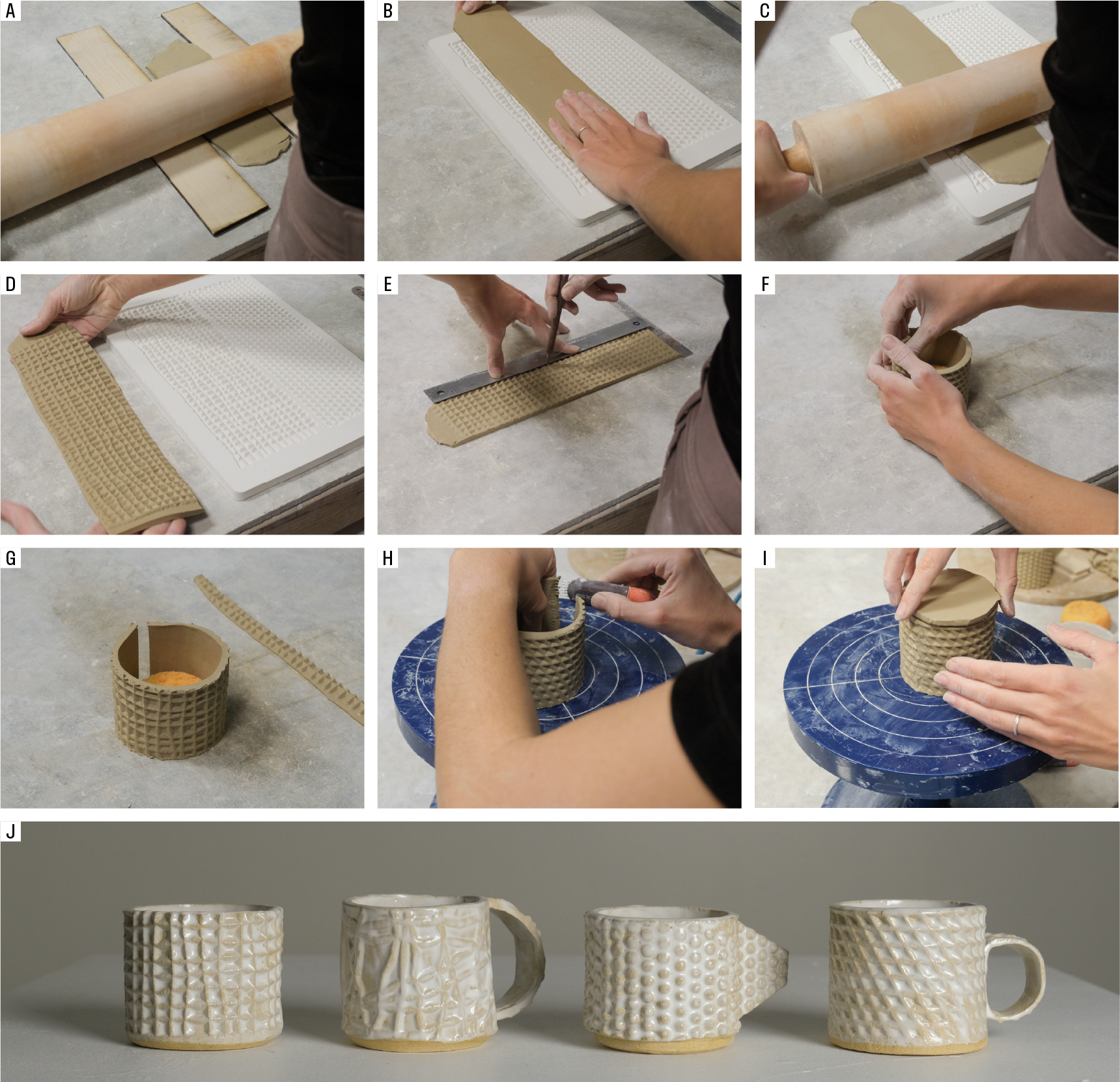

Finally, because I needed a little ceramic in the mix ;), I used millipath to carve plaster slabs.

I then rolled clay slabs on the textured plaster to create a set of cups. These cup exemplars show how using CNC-milled surface texture as mold emphasizes the aesthetic qualities of the carving end mill. The textures extend beyond their immediate use and become tools themselves. The cup-making process also demonstrates how CNC-milling actions can integrate complex manual ceramic decoration workfows to create functional artifacts.

c::